Stainless Steel Wire Inquiries

Buy direct from a US wire manufacturer for better pricing and reliable quality.

America’s Top Supplier of 316 Stainless Steel Wire

Custom 316 Stainless Steel Wire Products / Advantages of Wire Drawing / Tempering 316 Stainless Steel Wire / Metal Alloys / Certified USA Steel Wire Manufacturer

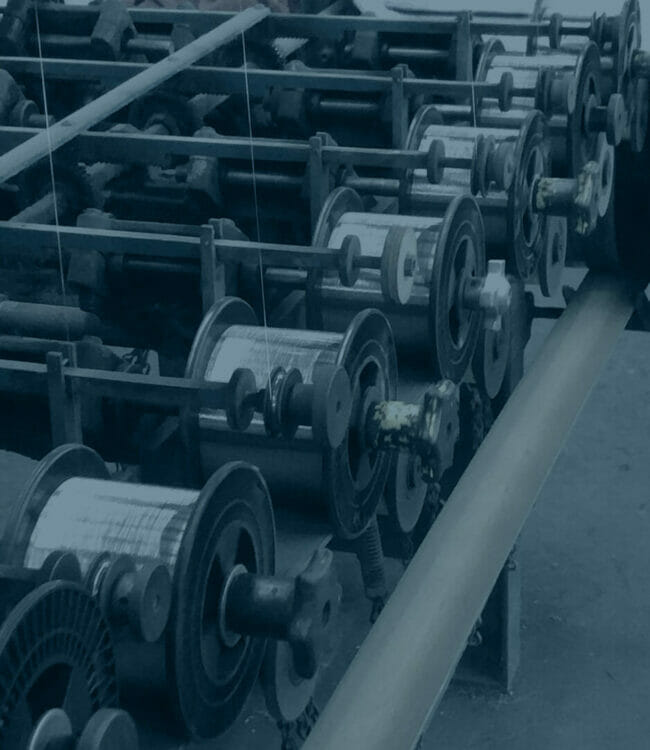

If you are seeking a reliable manufacturer of 316 stainless steel wire, you can depend on Brookfield Wire, LLC. We specialize in wire manufacturing, providing the highest quality round, flat, and shaped 316 stainless steel wire products. Our expertise in wire drawing ensures exceptional dimensional and processing control, which is crucial for achieving excellent surface finishing and high quality in 316 stainless steel wire.

As a leading 316 stainless steel wire supplier, we offer a wide range of sizes, tempers, finishes, and chemistries. Additionally, we can customize our wire solutions to meet unique application requirements, ensuring you get the perfect product for your needs.

The use of 316 stainless steel wire spans across industries and applications because of its versatility and durability. We can even temper 316 stainless steel wire, which enhances the metal materials by exposing them to high temperatures then cooling them quickly. Tempering, along with other wire forming processes, is part of what makes our 316 stainless steel wire production so high quality. You can count on Brookfield as your producers of 316 stainless steel wire.

If you are seeking stainless steel wire but are not sure exactly what kind you need, we can also assist in consulting with you regarding your desired application for the wire. In addition to 316 stainless steel wire we work with several other alloys, as indicated below. We can even package your wire in Bulk Spools, l lb. and 5 lb. Spoolsm, Bulk Coils and 1/4 lb. Handi-Pak Coils, New England Butt, Wardwell 16 & 24 Carrier, and Hacoba.

Custom Stainless Steel Wire Products

As one of the top 316l stainless steel wire suppliers, Brookfield offers a full range of products and services, and we have been manufacturing high-quality wire products since 1947. Our stainless steel wire is incredibly strong and versatile, so it can meet the requirements of virtually any application. 316 stainless steel wire is the ideal choice for applications in industries ranging from agriculture to aerospace. Our stainless steel wire products are also easy to clean, corrosion-resistant, and eco-friendly.

Brookfield Wire offers unparalleled experience in the manufacture of 316 stainless steel wire. We can draw wire to the perfect gauges, tempers, and finishes for your project at diameters from .006” to .250”. To further meet your expectations, we offer a wide selection of packaging and spooling options to meet your shipment and delivery needs.

Advantages of Stainless Steel Wire Drawing

Ultra-fine wire drawing services are a Brookfield specialty. With our manufacturing capabilities, we can offer the highest levels of precision for sizing, temper, and packaging. We draw countless tons of nickel, stainless steel, and other forms of wire every year, so you can trust our wire drawing experts to create the high-strength products you need. Here are some advantages of choosing Brookfield’s wire drawing process:

But that’s not all. Wire drawing also allows us to apply a full range of tempers and anneals. This allows us to tailor each product to the client’s exact application requirements.

Get a Free Quote on 316 Stainless Steel Wire

Trust the seasoned wire manufacturing professionals at Brookfield Wire, LLC, to supply you with premium quality 316 stainless steel wire.

Get a Free Quote on 316 Stainless Steel Wire

Trust the seasoned wire manufacturing professionals at Brookfield Wire, LLC, to supply you with premium quality 316 stainless steel wire.

Tempering 316 Stainless Steel Wire

Tempering is a crucial part of proper type 316 stainless steel wire manufacturing. This process enhances many aspects of the metal materials by exposing them to elevated temperatures and subsequently cooling them down.

Tempering will actively reduce the internal stress in the metal, increase corrosion resistance, decrease brittleness, and strengthen the metal overall. We offer a wide range of tempers from full annealing to full spring as well as intermediate tempers upon request. In fact, we can use our electric strand annealing furnaces to process any type of wire for shaping, rolling, and drawing.

We also give our customers access to a full range of metal materials. Global purchasing allows us to offer high-quality raw materials to meet any project requirements.

Metal Alloys | 300 Series Stainless Steel & More

With global purchasing, Brookfield has access to all alloys of 300 series stainless steel and many other high-quality metal alloys. This allows us to meet unique application requirements with ease and supply our customers with DFARS-compliant products.

We recommend use of the 300 series stainless steel versus 400 series because the 400 series lacks the nickel content characteristic of the 300 series. This lesser amount of nickel makes 400 series stainless steel more susceptible to rust and corrosion. Out of the 300 series, 304 and 316 are the most common forms. We use 316 stainless steel wire for applications where the wire will be able to resist acidic elements, high temperatures, and rust/corrosion.

In fact, we only use the highest quality materials from domestic or NATO resources. This ensures every customer receives the finest materials available for their stainless steel wire products. Check out our selection of metal alloys below:

300 Series Stainless Steel

Other Standard Alloys

Choose a Certified Company as Your 316 Stainless Steel Wire Supplier

Anyone searching for a manufacturer of high-quality 316 stainless steel wire can rely on Brookfield Wire, LLC. As an ISO 9001:2015 Certified Wire Manufacturer, we can develop the ideal wire solutions for your application.

Many of our clients include manufacturers that regularly purchase wire in bulk including brush wire, spring wire, welding wire, screen wire, and medical wire. We use our expertise and advanced equipment to fulfill high-volume orders with quick lead times and competitive pricing.

With more than 70 years in 316 stainless steel wire manufacturing, you can trust Brookfield to create the best wire products with the alloys, sizes, tempers, and finishes you need. We welcome any inquiries and questions about acquiring unique alloys and materials or discussing any of our other 50+ standard metal alloys, so do not hesitate to contact Brookfield Wire, LLC today!