Your Best Source for Stainless Steel Wire

Since 1947, Brookfield Wire has been a reputable wire company, specializing in drawing and shaping wire to meet the highest quality standards. Renowned for its expertise in wire drawing techniques and rigorous quality control, Brookfield Wire serves various industries, including aerospace and agriculture. The company’s nickel-based alloys and stainless steel wire are trusted in demanding applications globally.

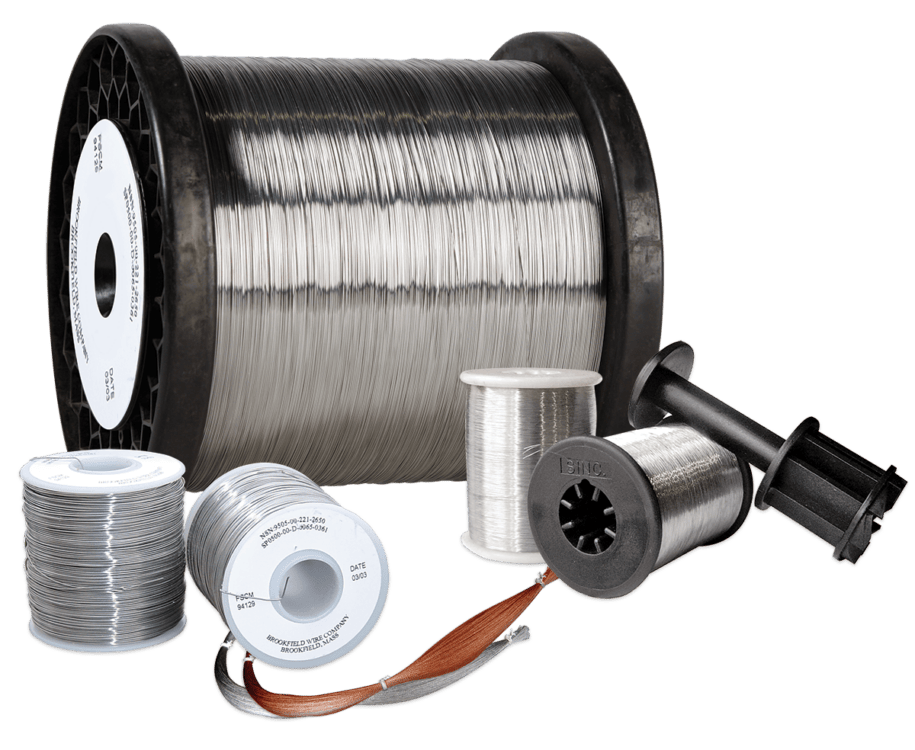

As a leading stainless steel wire supplier, Brookfield Wire offers precision wire drawing services tailored to specific gauge, temper, and finish specifications. The company can draw wire with diameters ranging from .006” to .250”. After the wire drawing process, Brookfield Wire provides a range of spool and package options to suit customer requirements, including coils, reels, Acro Pacs, and more. Whether clients need wire formed, flat, straightened, or cut wire, Brookfield Wire is well-equipped to handle diverse wire manufacturing needs.

Specializing primarily in stainless steel, nickel, and nickel-based alloys, Brookfield Wire excels in providing quick lead times and competitive pricing, setting it apart from other U.S. wire manufacturers. The company proudly offers DFARS-compliant wire materials, ensuring high-quality and reliably sourced metals for all clients. With a commitment to meeting customer needs and surpassing the highest demands, Brookfield Wire stands as a trusted partner in the wire industry.

Application Specifications

Get It Custom.

With over 70 years of experience in wire manufacturing, Brookfield Wire offers comprehensive services to meet various specifications. Specializing in wire forming, straight and cut wire, die-drawn shapes, wire drawing, custom tempers, and more, Brookfield Wire has the processes and expertise to fulfill diverse wire manufacturing needs.

For those searching for “wire manufacturers near me,” Brookfield Wire stands out, as the number of actual wire manufacturers in the U.S. is limited. While there are many wire suppliers, Brookfield Wire’s distinction as a wire manufacturer with extensive experience and expertise, particularly in challenging applications like aerospace wire, sets it apart. Whether clients require 316 stainless steel or a nickel alloy, Brookfield Wire can manufacture wire to precise specifications. Contact Brookfield Wire today to learn more or request a quote.

Need Wire Quickly

Get It Fast.

Brookfield Wire, with its extensive experience in the industry, understands the importance of meeting tight schedules and delivering high-quality wire products promptly. Recognizing that customers often seek swift manufacturing and delivery, Brookfield Wire stands out by offering efficient and effective wire drawing and forming processes without compromising on quality.

While some steel wire companies may prioritize speed over precision, Brookfield Wire ensures that the quick turnaround aligns with the specified requirements and maintains the product’s overall quality. Clients looking for a reliable solution that combines speed and quality can trust Brookfield Wire to deliver on schedule. Contact Brookfield Wire, LLC today for a fast and reliable wire manufacturing experience.

Flexibility & Excellent Service

Get It Right.

Brookfield Wire has earned the trust of countless industries globally, establishing a reputation for quality and exceptional customer service. Beyond offering competitive wire pricing and swift turnarounds, Brookfield Wire stands out by being DFARS-compliant, meeting the stringent standards required by various industries.

Despite the preference of some companies to work with a “wire company near me,” Brookfield Wire’s seamless collaboration and rapid shipping create a sense of proximity and responsiveness, regardless of geographical distance. The company serves clients worldwide and excels in industries with demanding wire standards, such as aerospace and medical. In these sectors, both speed and precision are crucial, and Brookfield Wire has consistently delivered on both fronts for over 70 years. Contact Brookfield Wire today to explore how their expertise can benefit your needs.

Precision Wire Drawing from a Wire Manufacturer Near Me

With over 70 years of expertise in drawing and shaping stainless steel wire, Brookfield Wire is a trusted source for various wire-related services. Leveraging their extensive experience, the team ensures the delivery of the right alloy, size, temper, and finish to meet specific wire requirements. Manufacturers frequently choose Brookfield Wire for bulk wire purchases used in diverse applications such as brush wire, welding wire, rope wire, cable wire, marine wire, spring wire, screen wire, medical wire, and more. The company possesses the equipment and knowledge to handle projects of any size.

For those in need of stainless steel wire or specialty wire products, Brookfield Wire, LLC is well-equipped to provide assistance. The available wire packaging includes options like bulk spools, 1 lb. and 5 lb. spools, bulk coils, and 1/4 lb. Handi-Pak coils, New England Butt, Wardwell 16 & 24 Carrier, and Hacoba.

The Brookfield Wire Difference

Brookfield Wire, LLC stands out as a distinctive wire manufacturing company, offering a level of longevity that sets it apart in the industry. With over seven decades of experience, the company has served various industries with stringent guidelines, including aerospace and the oil and gas sector. This extensive experience positions Brookfield Wire as a reliable partner with a deep understanding of diverse services, processes, and products. Choosing Brookfield provides the advantage of working with a wire company that combines decades of expertise with the ability to deliver bulk wire on time and within budget.

Stainless Steel Wire, Nickel Wire, & Many Other Quality Alloys

Brookfield Wire, LLC is at the forefront of custom wire manufacturing, specializing in 300 series stainless steel, nickel and nickel-based alloys. Equipped with electric strand annealing furnaces, the company has the capability to process a wide range of wire types, catering to industries such as automotive, medical, aerospace, and more.

With an extensive stock of 50 standard alloys, Brookfield Wire welcomes inquiries for hard-to-find alloys, demonstrating a commitment to customer satisfaction. The company employs global purchasing methods to secure high-quality raw materials from domestic and NATO sources, ensuring the provision of reliable wire products for every project. Explore the selection of metal alloys offered by Brookfield Wire below.

300 Series Stainless Steel

Other Standard Alloys

Industries Our Wire Company Serves

Brookfield Wire, LLC provides a comprehensive range of aerospace and aviation wires, including wire drawing, tag wire, bulk wire, spring wire, and custom cuts tailored for the most demanding aerospace applications. The company offers seamless wire prepared to exact specifications, serving the aerospace industry with reliable wire solutions.

Brookfield Wire specializes in various specialty alloys and metals, as well as cold heading and bar stock, meeting the specific requirements of the aerospace sector. The company is recognized as one of the top wire companies trusted for the aerospace and aviation industries. Among the popular alloys for aircraft wire, Brookfield Wire offers copper, Inconel, and Monel.

Brookfield Wire, LLC, stands as a reliable solution provider for industrial clients facing diverse challenges. With a wealth of expertise in metal alloys, custom cutting, wire drawing, and forming, Brookfield Wire is well-equipped to address a wide array of applications. The company’s commitment to putting client needs first ensures performance and quality, making it a trusted wire manufacturer.

Brookfield Wire, with its forming wire, straight and cut services, and wire drawing capabilities, provides reliable and versatile solutions for building and construction projects. The company’s reinforced steel products, responsibly sourced and DFARS-certified, cater to the needs of contractors, civil engineers, and architectural firms. As a wire company well-versed in the complexities of the construction industry, Brookfield Wire stands out as a dependable partner for construction-related applications.

Brookfield Wire offers an extensive range of automotive wire suitable for various applications and systems in vehicles. Whether it’s wire for springs or cold-formed safety wire, their automotive components are designed to meet the demands of complex automotive systems. As a leading wire supplier, Brookfield Wire is recognized for its quick lead times and attention to detail, ensuring timely solutions that help get vehicles back on the road efficiently.

Brookfield Wire takes pride in serving the farm, garden, and agricultural industries as one of the premier bulk wire suppliers in the United States. Their agricultural wire finds applications in various uses, such as crop protection, compost bins, critter control, and livestock barriers. Leveraging their wire mesh and wire drawing capabilities, Brookfield Wire provides superior solutions to meet the diverse needs of the agriculture sector. Their experienced team engages with clients to understand each scenario, ensuring the right product is chosen for specific applications.

In collaboration with the oil and gas industry, Brookfield Wire meets substantial product demands characterized by heat resistance, strength retention, and endurance. As a DFARS Compliant company, Brookfield ensures the use of high-quality and reliably sourced materials. This commitment allows oil and gas customers to explore cutting-edge technology and meet stringent requirements. Despite the challenges posed by high-demand products, Brookfield Wire stands out as an unmatched wire supplier in the industry.

Brookfield Wire, LLC plays a crucial role in supplying bulk Inconel*, Monel*, and stainless steel wire to various manufacturing sectors across the United States. Apart from offering bulk wire, the company provides custom-cut spools of wire on bobbins tailored to the precise requirements of each manufacturer. Stainless steel wire from Brookfield Wire is a vital component in numerous manufacturing processes, including safety wire (MRO) and lockout/tag-out procedures. For essential manufacturing components demanding precision, Brookfield Wire stands out as the leading wire company near me.

Marine wire faces the challenge of harsh and corrosive environments, requiring solutions that offer flexibility, safety, and corrosion protection. Brookfield Wire provides a comprehensive range of fine wire and alloys designed to perform at the highest level in the dynamic and corrosive conditions of marine environments. Whether it’s running wire or stayed rigging, Brookfield Wire delivers the solutions needed, establishing itself as one of the top wire manufacturers.

In the mining and exploration industry, where extreme conditions are the norm, Brookfield Wire plays a crucial role. From mining wire mesh to providing the wire for robust mining wire cables, Brookfield Wire relies on the highest-quality materials in the industry. The commitment to DFARS-compliant wire ensures advanced strength and corrosion resistance, making Brookfield Wire a top choice among wire companies in proximity to mining and exploration operations.

In the medical industry, precision and performance are paramount, and Brookfield Wire is a reliable supplier of medical wire designed to meet the highest standards. Offering cradle-to-grave solutions, Brookfield Wire ensures exact specifications from metal alloys to cut and shape. With a focus on supporting critical medical applications, the company provides a range of standard alloys, sizes, tempers, and finishes, making it a top choice among bulk wire suppliers in the medical field.